You've done it! You have received an order from a customer. Everything from marketing to final checkout has worked out well. Kudos! Now that order needs to reach the customer, that’s where order fulfilment comes in.

When a customer places an order on your eCommerce website, you are making a commitment that the desired product will be delivered to them within a certain time frame. Order fulfilment is basically the efforts you make to live up to that commitment.

It is a thankless job. Nobody pays attention to it when things are going well. But one mistake can bring the entire process and even the company’s reputation into question.

This article focuses on thoroughly understanding the order fulfilment process. It also includes different fulfilment models for eCommerce businesses.

What is Order Fulfilment?

Simply put, order fulfilment means delivery of the purchased product to the customer. It is the journey from “Your order is placed” to “Your order is delivered”.

Terminology Breakdown:

Order: The purchase order placed by a customer for product/s.

Fulfilment: Delivery of the product to the customer as the fulfilment of the promise made by the seller.

Order fulfilment definition seems simple and straightforward, it is a complex process. It involves supply chain management, inventory management, warehousing, and logistics. Fulfilment of orders is the final and the most resource-intensive stage of an eCommerce transaction.

Importance of Order Fulfilment

The order fulfilment process has a direct impact on the company’s costs, customer satisfaction and brand reputation. It is also one of the most important factors that you need to consider when scaling your eCommerce business or expanding into a new market.

Below are some of the reasons that highlight the significance of order fulfilment for eCommerce businesses.

Customer Satisfaction

For an eCommerce company, order fulfilment is about living up to the customer’s expectations. When the customer places an order, the seller is essentially making a promise that they will receive their desired product within a given time.

That’s why order fulfilment has a direct impact on customer satisfaction. According to a study by Voxware, 30% of shoppers are less likely to buy from a brand if their order is not delivered by the promised date.

Imagine how frustrating it would be if a customer placed an order with 2-day delivery. But, it arrives a week later. The customer would be even more disappointed if they received the wrong product. 16% of the shoppers would never shop again from a brand that delivered the wrong product.

Successful eCommerce order fulfilment is fast and efficient. Otherwise, you risk losing a customer.

Cost Optimisation

Order fulfilment process can be quite resource-intensive. You have to invest in inventory management, storage facilities, packaging equipment, labour, delivery vehicles, licences, and more. If you take the burden upon yourself, you will also have to find different vendors for different customer locations.

You don’t need to take control of the entire eCommerce order fulfilment process. You can assign the duty of delivering goods to third-party logistics (3PL). It will help you cut the cost of operations for storage and logistics.

With 3PL, you only have to pay for the services you use. You can control the stages that you want to manage and outsource the rest to a 3PL company. You can further cut down the cost of labour and management with order fulfilment automation.

Ease of Scaling up

When you think of expanding your eCommerce business, you first need to consider how you will deliver products to new customers. The flexibility of your order fulfilment strategy will dictate the speed of your transition into a new market.

Furthermore, free shipping and fast delivery are some of the most enticing deals to attract eCommerce customers. Both these options depend on your order fulfilment cycle time.

A reliable online order fulfilment process will help you maintain consistent customer satisfaction regardless of the territory or sales volume.

Order Fulfilment Process

The order fulfilment process hinges on speed and efficiency. It is a complex workflow with several variables that can cause delays or mistakes. Hence, it is necessary to understand each step of the process. So that you can mitigate the risks involved at various stages.

Order fulfilment in supply chain management involves receiving the products from the supplier, organisation of products, storage, inventory management, packing products for delivery, and finally shipping them off to the customer.

The overall order fulfilment cycle time depends on the synchronised performance at each stage.

Receiving Inventory

Unless you are dropshipping, you will first need to receive the products from a supplier. This is the stage where you have the least control as you are dependent on the proficiency of the supplier and their logistics partner.

Still, you can coordinate with them to create a streamlined workflow. This will help you accelerate the later stages of the eCommerce order fulfilment process where you have more control.

Inventory Storage and Management

Once you receive the products, you have to organise and catalogue them for storage. It’s important for you to store the products in a way that it is easy to find them for packaging and shipping. This is the stage where you have the most control and you can implement different inventory management systems to speed up the process.

Order Processing

This stage also offers much room for accelerating the fulfilment of orders. It hinges only on two actions: picking the product from warehouse shelves and packing it for shipping.

Picking the right products becomes fast and easy if you have an efficient inventory management system. It is imperative to double-check the order before packing to reduce the margin of error. Once you have matched the products with the order, you can pack them for shipping.

Shipping

At this stage, the product leaves your warehouse and begins its journey towards the customer. The journey of the product can vary depending on the distance between the warehouse and the delivery destination. Here again, you lose significant control over the process.

That’s why it is necessary to pick a dependable order fulfilment specialist so that the right products reach the right customer on time.

Handling Returns

If a customer returns the product, it again follows the same path as order fulfilment, only backwards. The product is picked from the customer’s location and shipped to the warehouse. There it is processed and added to the warehouse inventory.

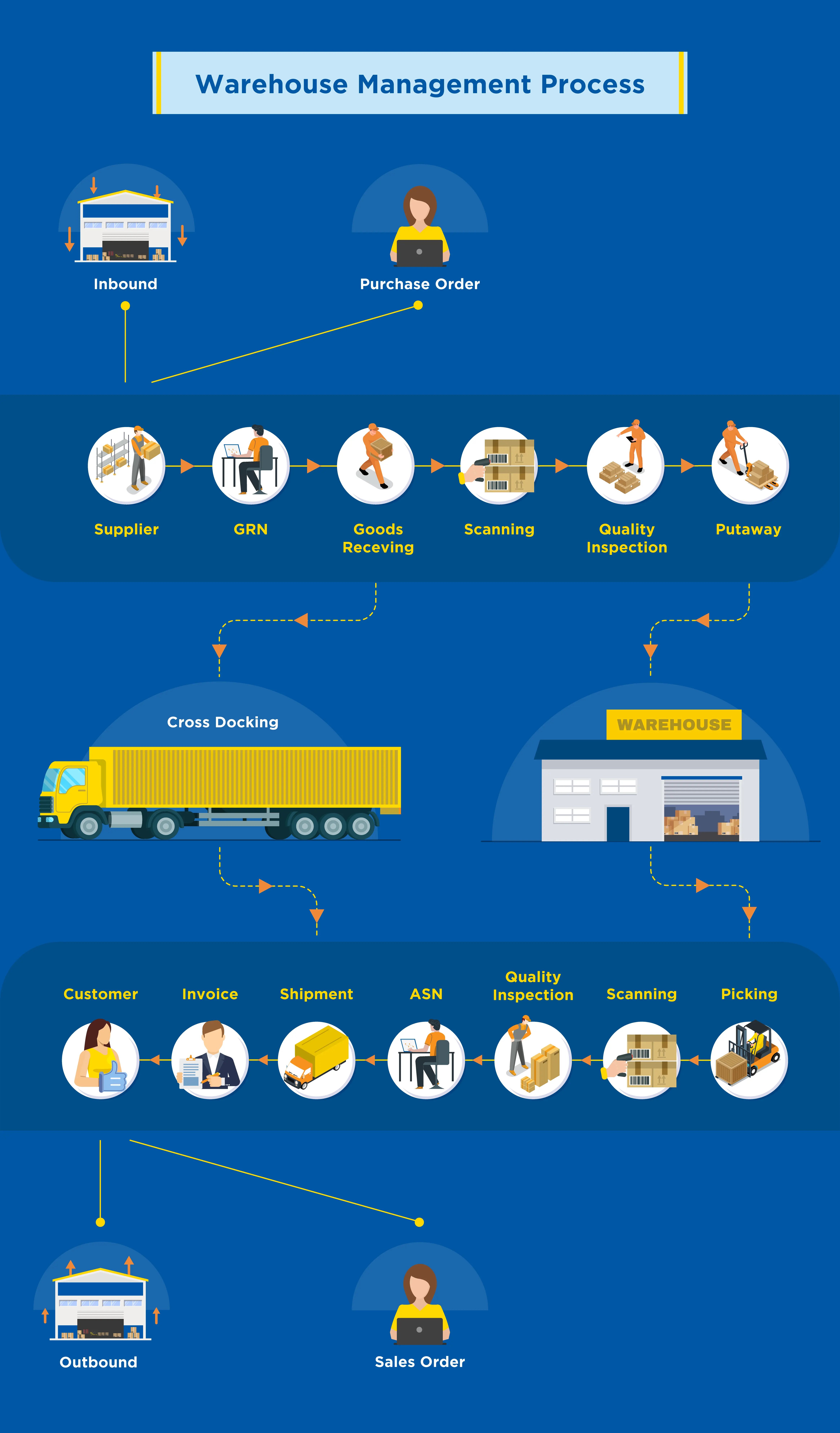

Order Fulfilment Process Flow Chart

When planning your order fulfilment process, you can use a flow as shown below to understand various stages of the product’s journey. You can change different variables in the order fulfilment process flow chart. Each change will show you how it affects delivery time and expenses.

Order Fulfilment Methods

There are four primary methods for order fulfilment. Each method offers a different degree of control over the process.

In-house or Self-Fulfilment

This method grants complete control and complete responsibility. With self-fulfilment, you are responsible for transporting the product from the supplier to the customer’s location without any help.

In-house order fulfilment requires investment in resources such as warehouses, equipment, labour, and logistics. It also requires you to manage a variety of people for different purposes. This model is only viable if you are operating at a small scale and only delivering locally.

Self-Fulfilment is Suitable for:

- Small Scale

- Low Sales Volume

- Local or Regional Customer Base

Pros:

- Complete control at each stage of the process

- Huge scope for order fulfilment automation.

- Scope for personalised service for customers

- Consistent brand representation

Cons:

- Heavy investment in infrastructure & human resources

- Difficult to manage long-distant & international orders

- Cost of order fulfilment fluctuates with customer location.

- Investment and complexity increases with scale

- Difficult to manage fluctuating demands

Third-party Logistics (3PL) Fulfilment

In 3PL, you outsource order fulfilment to an external agency, usually a logistics company. You can choose whether to outsource the entire process or parts of it. A 3PL company can receive products from your supplier, store them in their warehouse, manage the inventory, process your orders, pack the products, and deliver them to the customer's location.

You only have to deal with one company for the delivery of the products. The biggest advantage of 3PL order fulfilment is that you only have to pay for the services you use.

3PL Fulfilment is Suitable for:

- Large Scale

- High Sales Volume

- Widespread Customer Base

- Growing eCommerce Business

- Expanding into New Markets

Pros:

- Does not require investment in infrastructure

- Cost-Effective for both local and international deliveries

- Cost reduces with scale, while complexity remains the same.

- Easy to manage fluctuations in demand

Cons:

- Dependency on third-party services.

- Less control over the process and delivery time.

- Relatively difficult to automate.

- Less scope for personalisation and brand representation.

Dropshipping

In dropshipping, the eCommerce business only acts as the seller. Once the order is placed, the supplier or manufacturer of the product takes control of the order fulfilment process. They pick the products from their warehouse, pack them and ship them to the customer’s location.

The eCommerce business does not need to invest in anything, nor does it have to pay third-party logistics for delivery. They are only responsible for sales and facilitating the supplier with necessary information. The rest is done by the supplier or the manufacturer. But, if the supplier delays the delivery or if they deliver the wrong products, the eCommerce business has to handle the consequences.

Dropshipping Fulfilment is Suitable for:

- Reselling eCommerce Businesses

- Affiliate-based eCommerce Businesses

- New eCommerce Companies with low budgets

Pros:

- No responsibility for storage and maintenance.

- No upfront investment in inventory.

- Low overhead expenses.

- Easy to scale.

- Flexibility of remote operations.

Cons:

- Lower margins compared to other fulfilment methods.

- Less scope for personalisation and brand representation.

- Limited quality control.

- Longer delivery time for long-distant and international orders.

- Customer service becomes difficult in case of delays or wrong delivery.

Hybrid Order Fulfilment

Hybrid model is a blend of Self-Fulfilment, 3PL, and Dropshipping. You take control of certain aspects of the order fulfilment process and outsource the rest to a 3PL company or your supplier. This model is viable if you are selling a wide variety of products that require different order fulfilment approaches.

For instance, if you are selling assembled products, you can outsource shipping while you take control of product receiving, storage and packing. You can also outsource storage and inventory management to the supplier and outsource shipping to a 3PL company. Similarly, you can outsource international orders while managing local orders by yourself.

With hybrid order fulfilment, you customise the process as per your requirement. But this method also entails complex workflows with a large margin for errors. It requires transparency between all parties and careful monitoring at each stage.

Hybrid Order Fulfilment is Suitable for:

- Selling Customised Products

- Selling Multiple Products from Different Suppliers

- Ecommerce Businesses with Sufficient Storage Facilities

Pros:

- Huge scope for customisation of the order fulfilment process

- Balance between control and outsourcing

- Control over cost and process

Cons:

- Difficult to automate

- Complex order fulfilment process.

- Requires different SOPs for different orders.

- Huge margin for errors.

- Complexity increases with scale.

How to Determine the Right Order Fulfilment Strategy?

The right order fulfilment strategy for your eCommerce business depends on different variables concerning your products, customers, suppliers, resources, and so on.

You will need to consider several factors to determine which order fulfilment strategy can best serve your business and your customers. Here are some of them.

Size and Scale of Business

The right order fulfilment strategy depends on the scale of your business, the types of products you sell and the volume of orders you receive each month.

If you are just starting your eCommerce business, dropshipping is the right choice for you. The margins are low, but you get flexibility for scaling and you can relieve yourself from the workload of order fulfilment. But, if you want more control over the process and want to add a personal touch for your customers, you can choose self-fulfilment. But, these methods will serve you only up to a certain scale.

As the business grows, you will need to control the inventory and delivery time. You can no longer rely on dropshipping for this. Large volumes also require heavier investments in infrastructure and resources. These factors make self-fulfilment quite expensive. Once you start receiving a steady flow of orders and you wish to expand the business, it is advisable that you shift to 3PL or at least a hybrid model for order fulfilment.

3PL and hybrid models are also more efficient if you are selling a variety of products from different suppliers. Each supplier will have different protocols and delivery cycles. So dropshipping will create inconsistency in delivery time.

Customisation Requirements

The perfect eCommerce order fulfilment process for you also depends on the level of customisation that your products require. Depending on the complexity of customisations your products need before reaching the customer, you will have to alter your strategy for delivery.

If you are selling assembled products, then dropshipping is out of the question. This is especially true if parts of your product come from different suppliers or need special packaging before shipping. At the same time, if you are operating at a large scale and delivering to customers in different countries, self-fulfilment will be too expensive

In such scenarios, a hybrid fulfilment model is a sensible choice. You can receive products from the supplier, customise them at your order fulfilment centre, and then ship them to the customers..

You can partner up with an order fulfilment specialist, to manage the cost and reduce the burden at your end. This blend of self-fulfilment and 3PL will help you control the customisation process without investing heavily in logistics. You can cater to customers in far-off locations and still hold absolute control over product quality.

Target Market Location

Your order fulfilment rate depends on the location of three parties:

- Your Supplier

- Your Warehouse

- Your Customers

The relative distance between these three locations is crucial to define the ideal order fulfilment strategy for your business.If the warehouse and your customers are situated nearby, you can adopt self-fulfilment. If the supplier is located closer to the customers, dropshipping would be a viable option.

At short distances, you or your supplier can easily manage fast deliveries and it is easier to control the cost of delivery. But, as the distance grows, you will need help from the order fulfilment company. You can also adopt a hybrid model to assert control over certain parts of the process.

The most important thing to remember is that the cost of delivery is directly related to how far and how often a product moves before reaching the customer. Before locking down on a strategy, you can create an order fulfilment process flow chart to understand the journey of the product for each model. Then choose the one, where the product has to travel the least.

Tech-stack and Sales Channels

Your order fulfilment process will change depending on where you sell your products. Most eCommerce businesses sell their products through a variety of channels like online marketplaces, native websites, eCommerce stores, etc. Many of these have their own order fulfilment solutions.

You might have to adopt multi-channel order fulfilment if you are selling products on third-party marketplaces such as Amazon, Shopify, Etsy or eBay. This means that the orders placed for your product on Amazon are fulfilled through Amazon FBA. This is equivalent to dropshipping. But, you need a different fulfilment model for orders placed on your website.

Multi-channel order fulfilment creates an uneven customer experience. For instance, the customers purchasing through Shopify stores may receive the products on time, while those that brought the products through Amazon may experience delays. That’s why many eCommerce companies adopt omnichannel order fulfilment. In this method, they control the fulfilment process regardless of the sales channel.

With omnichannel order fulfilment, you can ensure a consistent customer experience. But, it requires investment in storage and logistics infrastructure. This method also requires investment in technology for order fulfilment automation as you will be juggling data from different sales channels.

Order Fulfilment Best Practices

Despite many differences in fulfilment models, there are a few fundamentals of the order fulfilment process that remain unchanged. Inventory Management, Storage, and Logistics are the cornerstones of all fulfilment processes. The following best practices focus on improving speed and efficiency for these three fundamental stages.

Plan your Warehouse Flow

You have the most control over the fulfilment of orders at your warehouse. It is also the centre point for the entire process. From receiving products to shipping them, you have ample space for optimising your warehouse process flow so that you can ultimately reduce order fulfilment cycle time.

The first two steps to improve workflow at the warehouse are selecting the right location for the warehouse and planning the optimum layout within it. The next step is to streamline the receiving process for the products. After that, you should turn your attention to inventory management and storage.

Your order fulfilment rate is highly dependent on how fast warehouse staff can find and pack the stored products. You can improve the speed and efficiency of this process by investing in equipment to assist your warehouse staff.

A clockwork-like warehouse flow will speed up the eCommerce order fulfilment process.

Outsource Fulfilment to a 3PL Provider

A 3PL order fulfilment company has already invested in the necessary infrastructure for storage, packing, and delivery. It would be much easier and cost-effective for you to outsource the fulfilment of orders to them rather than take the burden on your head.

This practice is especially helpful if you are starting out or expanding to new territories. Instead of making an upfront investment, you can utilise the infrastructure of the 3PL company for fast and efficient order fulfilment solutions. Aside from infrastructure, you also benefit from the long-running experience of your 3PL partners in the region.

You can save money, manage more orders, and ensure timely delivery with the help of an order fulfilment specialist.

Use Technology

Order fulfilment automation is possible at almost every stage of the process. You can use software, robots, and equipment to speed up the process and reduce the margin of error.

Automation software can help you link different steps to improve the order fulfilment rate. For instance, you can link sales, inventory management and warehouse management for an unimpeded flow of accurate information without the need for human intervention.

Similarly, you can connect inventory management and warehouse management software with robots to speed up the picking process. Investment in robots and specialised equipment can also help with inventory receiving, organisation, and packing.

Furthermore, by employing software and automation in logistics you can accurately track order fulfilment status and keep your customers informed of the same. Investment in the right technology will make it easier for you to scale your eCommerce business.

Train your Warehouse Team

A warehouse staff comprises a variety of individuals trained in different fields. If you want your warehouse to function like clockwork, these individuals have to work as a team.

The best example of team training comes from sports. Athletes of different skills undergo training so that they can play as a single unit and serve a unified purpose. Your warehouse staff would benefit from role-specific training as well as team-building sessions.

Smooth warehouse operations depend as much on interpersonal cooperation as they do on the abilities of individual employees. By incorporating training regimes, you can mould different individuals into a team that serves a unified purpose.

Wrapping Up

When preparing the eCommerce order fulfilment process you should always remember the end goal: Customer Satisfaction. The entire order fulfilment process hinges on three criteria:

- Customer receives the right product.

- The product is delivered within the promised time.

- The product is not damaged during delivery.

At the same time you will also need to adopt practices that are suitable for your business. Your order fulfilment process should be cost-effective, sustainable, scalable, and efficient.

The key challenge for eCommerce businesses is to find the balance between customer satisfaction and business needs.

PACK & SEND offers streamlined order fulfilment services for eCommerce businesses of all sizes. While you focus on getting more customers and expanding your business, PACK & SEND will take care of delivering those customers, no matter how far away.

More than order fulfilment solutions, PACK & SEND offers the right balance between your business interests and customer satisfaction.

Frequently Asked Questions (FAQs)

What does fulfilment mean?

Fulfilment or order fulfilment is the process through which a customer receives their purchased product. It is the journey of a product from the hands of the seller to the hands of the customer. In the case of online order fulfilment for eCommerce businesses, fulfilment involves inventory management, product storage, packaging and shipping.

What is the first step in order fulfilment?

The very first step in order fulfilment is receiving the inventory from a supplier. This inventory is then stored at a warehouse or order fulfilment centre. Then it is packed and shipped to the customer. If you are both the manufacturer and the seller, then picking products from storage would be the first step of online order fulfilment for you.

What does dispatched mean in delivery?

When a product is dispatched, it means that it has been packed and handed over to the delivery agent. At this stage of the eCommerce order fulfilment process, the product has left the warehouse. To put it simply, “dispatched” means the product is on its way to the customer’s location.

What is the difference between order processing and order fulfilment?

Order processing is the part of fulfilment where the customer’s order is prepared for delivery. This includes picking the products from storage, packing them, and preparing them for delivery. On the other hand, order fulfilment also involves steps before and after order processing. It includes receiving products from suppliers, inventory management, and logistics.